Capabilities / Non-Food Industries / Personal Care

Personal Care Manufacturing Automation

Solutions to suit every sized business.

Solutions to suit every sized business.

Whether you’re a multinational producing thousands of units an hour or a growing independent brand making short-run batches, Foodmach designs automation that fits your operation and grows with it.

From first conversation to full line integration, our process is designed around your needs, compliance requirements and growth plans.

Jump to:

- Small, independent manufacturers

- Mid-sized manufacturers & contract packers

- Multinational/large manufacturers

- How we work

- Why Foodmach?

Here’s how we can help you:

Smaller Manufacturers

We can design, supply and integrate:

- Modular entry-level automation that can grow with your business.

- Affordable filling systems for small-batch runs with quick cleaning and setup.

- Compact case packers with minimal changeover time.

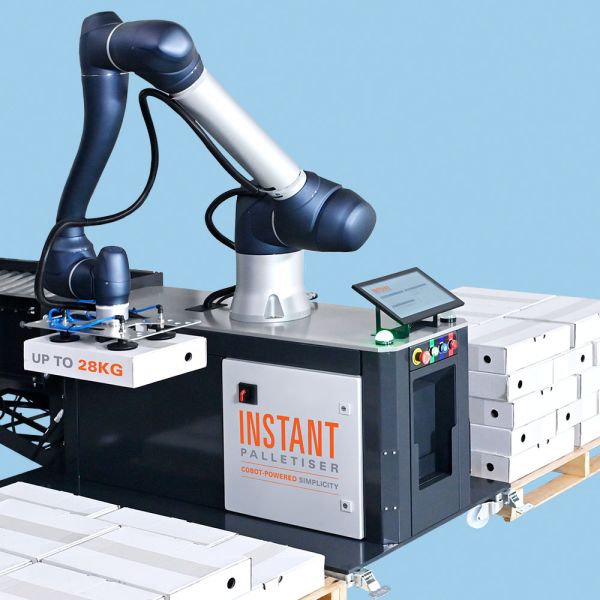

- Collaborative palletisers that move between lines without safety fencing.

- Semi-automatic or compact automatic stretch wrappers.

- Easy-to-use coding, labelling and inspection options—from benchtop systems to integrated sensors—for reliable compliance without overcapitalising

- Entry-level line control solutions to give operators clear, centralised control without overcomplicating production.

- Simple recipe-driven settings to reduce manual adjustments and speed up small-batch changeovers.

- Basic paperless tools such as digital production logs and label printing from centralised data to replace manual paperwork.

- Essential quality control features to ensure code accuracy, label compliance and seal integrity without heavy investment.

While you’re growing, it’s about scalability, simplicity and achieving professional compliance standards without overcapitalising.

Mid-Sized Manufacturers

We can design, supply and integrate:

- Integrated end-of-line automation linking case packing, palletising, wrapping, labelling and inspection

- Flexible filling systems for varied pack formats with quick changeovers

- Multi-format case packers for bottles, jars, tubes and cartons

- Robotic palletisers matched to footprint, speed and payload requirements

- Automatic stretch wrappers to improve stability and reduce film waste

- Coding, labelling and inspection systems fully integrated with ERP/MES for accurate, traceable compliance

- Scalable line control systems that unify varied OEM equipment into a single operator interface for improved coordination and reduced downtime.

- Recipe-driven changeovers to manage frequent SKU changes efficiently and minimise manual setup errors.

- Transition to paperless manufacturing with digital work instructions, batch tracking and simplified reporting.

- Targeted quality control integrating critical in-line inspections with centralised data storage for easy compliance documentation.

Mid-sized manufacturers and contract packers need flexibility for extra SKUs, space efficiency and cost-effective compliance.

Larger Manufacturers

We can design, supply and integrate:

- Turnkey high-speed packaging lines integrating filling, case packing, palletising, wrapping, coding, labelling and inline inspection

- High-speed filling systems for a range of viscosities with rapid CIP/SIP

- High-output multi-format case packers with servo-driven recipe-controlled changeovers

- Multi-robot palletising cells with automated slip sheet handling, strapping and stretch hooding

- Automatic stretch wrapping with load validation, integrated weighing and WMS connectivity

- Advanced coding, labelling and inspection platforms integrated with ERP/MES/WMS and GS1/GDSN standards for global compliance and audit-ready traceability

- Advanced, multi-line control with centralised line management execution to synchronise high-speed operations and optimise OEE across multiple plants.

- Complex recipe-driven manufacturing with full ERP/MES integration for rapid, validated changeovers across global product portfolios.

- Fully paperless manufacturing with digital batch records, e-signatures and automated compliance reporting for multiple markets.

- Integrated quality control capturing in-line data in real time for audit-ready traceability and continuous improvement.

As a multinational/large manufacturer, we help you achieve maximum uptime, global compliance and performance at scale.

Working with Us

We design what’s right for your business—not just what’s in our catalogue.

While we only recommend the best in class for every category, our speciality is integration, and we routinely design turnkey lines that combine machines from multiple OEMs into one seamless, high-performing system.

Our goal is to build a long-term partnership that grows as you do.

Here’s how we do it:

1. Understand & Identify

We begin with a packaging line audit or consultation to uncover bottlenecks, compliance risks and opportunities.

We’ll map your current performance and pinpoint where you can gain throughput, reduce waste or simplify compliance.

2. Design & Recommend

Our engineers design a solution scaled to your tier, from modular entry-level automation to fully integrated high-speed turnkey lines.

We’ll recommend the right mix of technologies to meet your performance, space and budget requirements.

3. Build & Integrate

All manufacturing, assembly, programming and testing happen in-house.

We manage installation, connect your new equipment with existing ERP/MES/WMS systems and provide hands-on operator training.

4. Support & Evolve

We deliver ongoing service, upgrades and optimisation so your automation can adapt to changing SKUs, compliance standards and market demands.

Where Are You in Your Journey?

Whether you’re exploring automation for the first time or upgrading to the latest integrated technology, Foodmach will:

- Pinpoint your biggest opportunities for gain

- Design a solution matched to your scale and operations

- Deliver on time, on budget and fully compliant with TGA/APVMA and GS1 standards

Book your free packaging line audit and see what’s possible for your business.

Did you know?

While the name Foodmach is synonymous with world-class line integration, palletising, depalletising and conveying, we also provide:

- Service & support

- Factory relocations

- One-Shot Truck/Trailer/Container Loading

- Engineering & fabrication services

- A wide range of third-party technology products

Read More: